Industry of machinery tools contributes an specific role to supply the engineering equipment for the national economy contribution. The philosophy of machinery as an area of knowledge in the last 15 years is actively studied by domestic and foreign scientists primarily in terms of identifying common patterns and principles of machinery development, due to the emergence of new technologies, changes in scientific, technical and engineering activities. Philosophical reflection of machinery reveals not only its essence, but also the attributive properties of a man, society and culture [1].

Customer nowadays triggers product decisions purchase according to subjective factors such as convenience, simplicity and pricing. Customer spends their capital on what feels right and are often unable to provide an explanation of their reason. While there is no simple formula to design a product that can be exactly successful in the market, inclusion of the needs of the target population in the design stage is an essential part of the process cycle. The design of the product is trusted to be one of the most necessary factors influencing the triumph of the product in a market, the interaction of the market atmosphere and the new product execution strategy, includes the product itself (e.g. product design, product advantages) [2]. Above explanations becomes the reason that encourages our research on upgrading engineering tools product redesign.

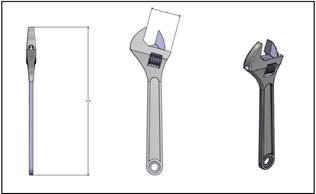

A wrench (or spanner) is a tool used to provide grip and mechanical advantage in applying torque to turn objects usually rotary fasteners, such as nuts and bolts or keep them from turning [3]. The most common shapes are mentioned as open-ended spanner and ring spanner. The term wrench refers to various types of adjustable spanner. In United States, wrench is the standard term and its most common shapes are known as open-end wrench and box-end wrench [4]. In American English, spanner refers to a specialized wrench with a series of pins or tabs around the circumference (these pins or tabs fit into the holes or notches cut into the object to be turned.) In American commerce, such a wrench may be called a spanner wrench to distinguish it from the British sense of spanner. Higher quality wrenches are typically made from chromium-vanadium alloy tool steels and are often drop forged [5].

Researcher gather the quantitative data for conventional product design that exists currently, basis on the collective research, design, development, machining and distribution-marketing costs. Each project was aligned qualitatively according to the main type of particluar involved-product design (e.g., furniture, CNC processing, engineering tools), engineering design, engineering plus industrial design and graphic design. The project deliverables were also rated qualitatively and quantitatively: first consideration, whether the project will be implemented (put and run into production), then second, its financial and business perspective and finally indirect benefits such as learning design-management skills [6].

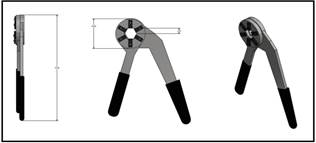

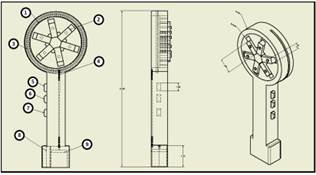

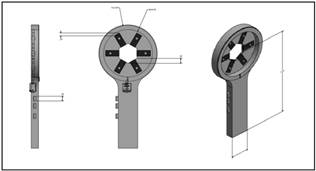

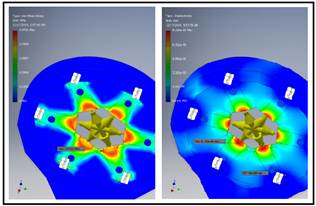

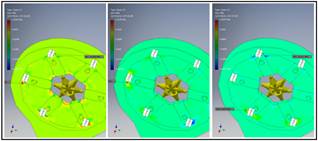

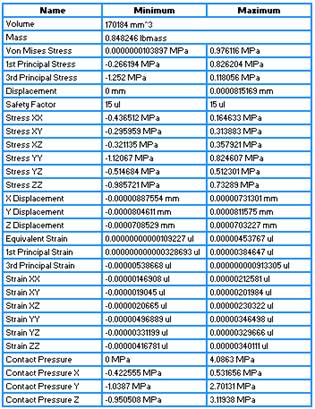

This paper explains and provides the development and analysis stage of new wrench product design due to formulation of bio-electromechanical mechanism and ergonomic aspect consideration. Nevertheless, the new design zooms on design of grip mechanism to minimize the required human-energy along the operation of tools and with the proposed materials to be used, its material also analyzed with some analysis parameter.

Literature Review

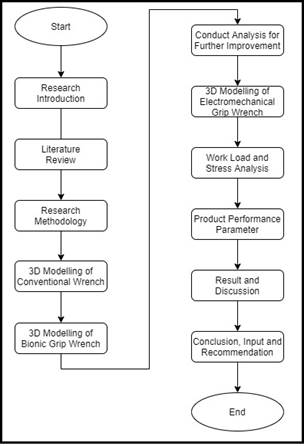

Following the history of the development of tools, which is identical to the history of mankind, Kapp established that rebuilding the environment, man unconsciously reproduces his organs, their shape, function and he knows himself, based on these artificial creatures. The process of organ projection is a gradual transition from the natural body in itself to the artificial body for itself [7], it can be both unconscious, instinctive and conscious, rational and systematic. The process of knowledge of machinery and human self-knowledge, which is always due to artificial organs and mechanical devices according to the concept of E. Kapp can be represented schematically as follows (Figure 1).

The concept of multipurpose product design is based on a broader research area of product family design. Product family design is a way to achieve cost-effective mass customization by allowing highly differentiated products to be developed from a common platform [8]. Function-based modular product architecture aims to identify the common modules for cost effective design [9]. The idea of product platform can be extended for flexible products with similar base module and variable functions to satisfy a larger set of customer needs [10].

Viswanathan et al. [11], categorized the guidelines for multi-purpose product design, a qualitative content analysis of product reviews was performed on the customer reviews collected from a randomized sample of 28 mechanical and electromechanical multipurpose products. The textual information in the reviews is cleaned up and analyzed using the formalized content analysis technique. They summarized two general rules were used to choose the products suitable for analysis: (1) the product must have at least two major purposes and (2) the product must have at least 10 reviews written by purchasers. The customer reviews provided by vendor-verified purchasers were copied to a text document. The main steps in the content analysis procedure implemented in this study are: the elimination of unwanted data, preparation of the data, initial sorting of the data and the inter-rater analysis [11].

In regards of customer satisfaction survey, Viswanathan et al. [11], conducted further investigation on the insights gained from the content analysis. The survey was designed to address customer preferences about the purpose, structure and cost of a multipurpose product.

The information was collected from a 100 participants via paid survey collection tool surveymonkey.com. The survey specifically investigated different aspects of multipurpose products such as: why they prefer it, how they carry it and what functions they prefer. The survey results indicated that most people prefer multipurpose products when they like to be prepared for unexpected situations [11].

Based on the results from the content analysis and the survey, the following guidelines about purposes, functions and interfaces, structure and cost are formulated to aid designers in the development of new multipurpose products [11]:

Purposes: Identify the target population for the product and determine the purposes accordingly. Use a strategic search for the purposes desired by the users-a review of the customer feedback on similar products could provide useful insights. Anticipate all possible purposes of the product, both intended and realized – it is critical to consider as many purposes as possible

Figure 1: Stages of knowledge of machinery and human self-knowledge by E. Kapp

Functions and Interfaces: The interfaces between functions should be efficient and the functions should not interfere with each another. While adding multiple functions to the product, do not compromise on the quality of the products or execution of the primary function (s)

Structure: The product architecture positively or negatively affects the product’s intended or realized purposes. The structure of the product should also allow ease of assembly, ease of cleaning and ease of storage

Cost: Wherever possible, keep the cost same or lower than the individual products. The higher cost is justified only when the product is very well made

Above four development criteria of new product development should be the basis and or the fundamental aspect this paper aims for. Purpose, function and interface, structure and cost are considered when applying product redesign concept to a conventional wrench to an advanced one.